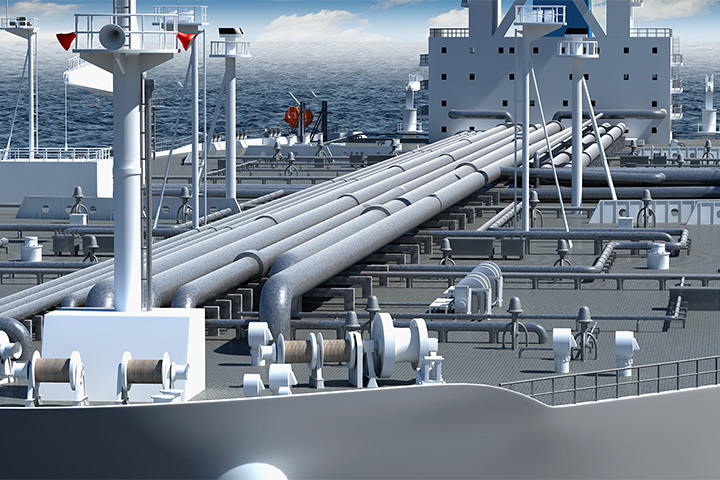

Marine & Oil Industry

Technologies ACG Technology Limited

Unit 20B, Beckett Way, Park West Business Park, Dublin 12, D12 T2NF

East Europe (Polish, Russian): +48 515 140 434

West Europe, USA, Canada: (English) +353 87 757 4750

Middle East & Asia: (Arabic, English) +48 602 306 266

contact@acg-tech.eu

orders@acg-tech.eu

EG-540 Oil demulsification and separation.

EG-540 is an innovation in the de-emulsification and water separation of oils/fats/hydro carbons within various industries and with numerous applications replacing centrifuge process. The EG-540 process is cost effective, improves productivity and obtains better results than any other chemical process. EG-540 is non-hazardous and the solution is non-flammable and biodegradable, EG-540 out performs all other competing chemicals and processes.

EG-540 is a concentrated solution of low-basicity, EG-540 breaks the emulsion/breaks micelles by lowering the interfacial tension thus separating water, dust, ashes, metals, chemical compounds and solids from all types of fats and oils including mineral, vegetable and animal.

This new and revolutionary product has been designed for industries including the petrochemical, oil production and oil recycling.

One of the numerous applications of this product is for the recycling of oil from water contaminated fluids as found in Ship bilge tanks, Our formula is simply 0,5% - 1% EG-540 per volume of contaminated material, with this ratio you will obtain oil within the 1st class scale of recycled oil. ie; oil with 0,2 to 5% of water contamination. Our average water contamination after 36 hours treatment is around 1 %.

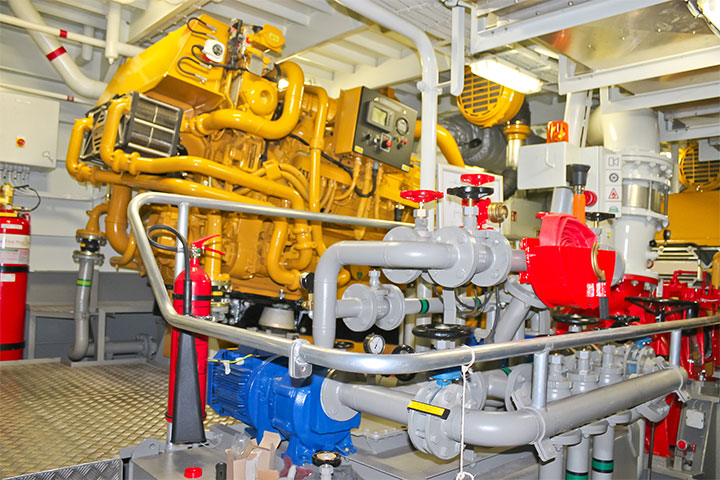

Typical description of EG-540 process on marine waste oil:

- Example – Marine waste oil initially may have 20-30% of oil and 70-80 of water. To make process most cost effective we advise to separate free water before EG-540 process. After initial gravity separation, we can obtain 60-70% of oil and 40-30% of water. Based on a 50 tonne tank of marine waste water of which 70% is emulsified oil, contaminated with 30% of water, process will require 500 kg of EG 540 (1%) to be added to storage tank preheated to 60-80 Celsius (depend on contamination and expected time to finished the process).

- The product is simply added into the tank and stirred / agitated then left to work without additional heating and agitating.

- During the fluid separation process samples at various levels within the tank can be taken with the process completed when the samples circa mid tank and top tank have obtain expected average.

- The average time to complete the de-emulsification and separation process is 24 - 36 hours, depending on the type of oils and contaminants, the process can take a further 12 to 24 hours to complete depends on expected result , for example water below 0.8% to match PFO standards may take 48 hours.

EG-360 Hydrocarbon, grease, oil and general surface cleaning.

EG-360 is an innovative, non-hazardous, non-flammable, biodegradable, non-solvent degreaser and cleaner.

EG-360 is a safe environmentally compliant cleaning solution used for many applications including degreasing and oil emulsification.

EG 360 is used by several large companies and ports in Europe. It is proven to be safe, economical and very effective.

EG-360 can be used in ATEX Zone 0 (gases/vapours), area's in which an explosive mixture is continuously present or present for long periods.

EG-360 applications include:

- Cleaning storage tanks.

- Cleaning fuel delivery trucks.

- Cleaning motor vehicles, fuel/ bitumen trailers.

- Cleaning and breaking down residues in cisterns and silos.

- Cleaning and restoring pipelines.

- Sludge and debris removal in separators and centrifuges.

- Cleaning within industrial installations.

- Cleaning production and storage areas, areas where hydrocarbons are produced, used or kept.

- Numerous cleaning applications in tanker ships, oil depots etc.

- EG-360 also removes moss and algae from all surfaces.

- Cleaning and restoring marina boardwalks and pontoons, ship and yacht hulls and decks including wood surfaces.

- Engine & transmission room cleaning.

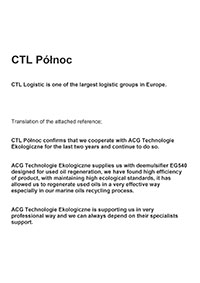

About us:

ACG-TECH is the inventor and manufacturer of a range of industry leading and innovative bio-chemical products for use within the refining and marine industry with particular focus on the process of waste oil regeneration.

Our De-emulsifier/Separator products are safe and harmless to the environment and afford significant reduction in processing times and costs.

We produce innovative, non flammable, non hazardous, bio degradable, de-greasing and washing formulae for Industries including Engineering, Marine, Energy, Refining.

Through Research and development in our laboratories by our Chief Scientist and in cooperation with The Polish Academy of Sciences, research Institutes in Germany, Denmark, Sweden, Austria, Spain and Brazil we continuously strive to improve our already proven products and processes.

Our company's products and processes will assist you in creating greater efficiencies, improved productivity and greater profits within your business.